- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Two basic bending process of acrylic sheet

2023-08-02

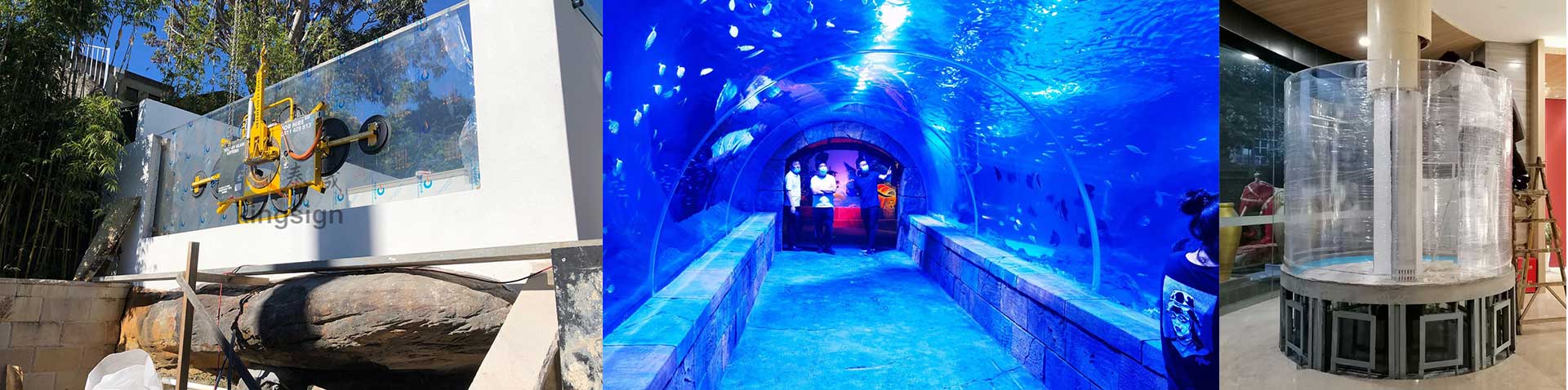

Acrylic has superior advantages in plasticity, today, we will talk how to achieve the final acrylic products by hot bending.

Acrylic sheets usually two types bending process.

One is partial area hot bending. To prepare particular size acrylic sheet, use high temperature mold sticks to heat and melt the correct position. Generally, extruded or good hygroscopicity acrylic sheets heating temperature at 130-135℃, cast acrylic sheet usually at 140-145℃. If acrylic sheet not virgin new materials(we can including recycling acrylic), the heating temperature will be relatively lower than virgin new acrylic sheets. Meanwhile, it is not suitable to heating too long length by this type process. If too thick acrylic sheets to bent, it is not applicable for this processing.

The second bending process is to heating entire acrylic sheets, and finish the bend in the help of molds. We produce the particular shape molds in advance. Then, put acrylic sheet on the molds together into oven, calibrated position, then supervised by experienced workers. Acrylic sheet will soften and fit onto the mold with the high temperature of baking. During this process, it is necessary to control the temperature, can’t be too high temperature. Finally, move out of the molds, waiting the acrylic cooling and shaping forming. Then get the customized bent products.

Kingsign produce different types acrylic sheets, whatever big or small, it is ok to finish by acrylic and our production. Send inquiry to us if you have needs.