- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Acrylic properties

2022-04-27

About acrylic properties as following

1. Mechanical properties

1.1 Polymethyl methacrylate has good comprehensive mechanical properties and ranks in the forefront of general-purpose plastics. The tensile, bending, and compression strengths are all higher than polyolefins, and higher than polystyrene, polyvinyl chloride, etc., and the impact toughness is poor. , But also slightly better than polystyrene. The cast bulk polymerized polymethyl methacrylate sheet (such as aerospace plexiglass sheet) has higher tensile, bending, and compression mechanical properties, and can reach the level of engineering plastics such as polyamide and polycarbonate.1.2 Generally speaking, the tensile strength of polymethyl methacrylate can reach the level of 50-77MPa, and the bending strength can reach the level of 90-130MPa. The upper limit of these performance data has reached or even exceeded some engineering plastics. Its elongation at break is only

1.3 2%-3%, so the mechanical properties are basically hard and brittle plastics, and have notch sensitivity, which is easy to crack under stress, but the fracture is not as sharp and uneven as polystyrene and ordinary inorganic glass. . 40°C is a secondary transition temperature, which is equivalent to the temperature at which the pendant methyl group starts to move. Above 40°C, the toughness and ductility of the material will be improved. Polymethyl methacrylate has low surface hardness and is easy to scratch.

1.4 The strength of polymethyl methacrylate is related to the stress time, and the strength decreases as the time increases. The mechanical properties of polymethyl methacrylate (oriented plexiglass) after stretching and orientation are obviously improved, and the notch sensitivity is also improved.

1.5 The heat resistance of polymethyl methacrylate is not high. Although its glass transition temperature reaches 104°C, the maximum continuous use temperature varies between 65°C and 95°C depending on the working conditions. The heat distortion temperature is about 96°C (1.18MPa), Vicat softening point is about 113°C. The heat resistance can be improved by copolymerization of monomers with propylene methacrylate or ethylene glycol diester acrylate. The cold resistance of polymethyl methacrylate is also poor, with an embrittlement temperature of about 9.2°C. The thermal stability of polymethyl methacrylate is moderate, better than polyvinyl chloride and polyformaldehyde, but not as good as polyolefin and polystyrene. The thermal decomposition temperature is slightly higher than 270℃, and its flow temperature is about 160℃. There is a wide range of melt processing temperature.

1.6 The thermal conductivity and specific heat capacity of polymethyl methacrylate belong to the middle level in plastics, which are 0.19W/M.K and 1464J/Kg.K, respectively.

2. Electrical performance

Since polymethyl methacrylate contains polar methyl ester groups in the side of the main chain, its electrical properties are not as good as those of non-polar plastics such as polyolefin and polystyrene. The polarity of the methyl ester group is not too great, and polymethyl methacrylate still has good dielectric and electrical insulation properties. It is worth pointing out that polymethyl methacrylate and even the entire acrylic plastics have excellent arc resistance. Under the action of an arc, the surface will not produce carbonized conductive paths and arc tracks. 20°C is a secondary transition temperature, which corresponds to the temperature at which the pendant methyl ester groups start to move. Below 20°C, the pendant methyl ester groups are in a frozen state, and the electrical properties of the material will be improved compared to when it is above 20°C.

3. Solvent resistance

3.1 Polymethyl methacrylate can withstand relatively dilute inorganic acids, but concentrated inorganic acids can make it corrode and alkali-resistant, but warm sodium hydroxide and potassium hydroxide can make it corrode and can be salt-resistant It is resistant to aliphatic hydrocarbons, insoluble in water, methanol, glycerin, etc., but can absorb alcohol and swell and cause stress cracking. It is not resistant to ketones, chlorinated hydrocarbons and aromatic hydrocarbons. Its solubility parameter is about 18.8 (J/CM3) 1/2, and it can be dissolved in many chlorinated hydrocarbons and aromatic hydrocarbons, such as dichloroethane, trichloroethylene, chloroform, toluene, etc., vinyl acetate and acetone can also make it Dissolve.

3.2 Polymethyl methacrylate has good resistance to gases such as ozone and sulfur dioxide.

4. Weather resistance

Polymethyl methacrylate has excellent atmospheric aging resistance. After 4 years of natural aging test, the sample has a slight decrease in tensile strength and light transmittance, a slight yellowing in color, and a decrease in crazing resistance. Obviously, the impact strength has been slightly improved, and other physical properties have hardly changed.

5. Flammability

Polymethyl methacrylate is easy to burn, and its limiting oxygen index is only 17.3.

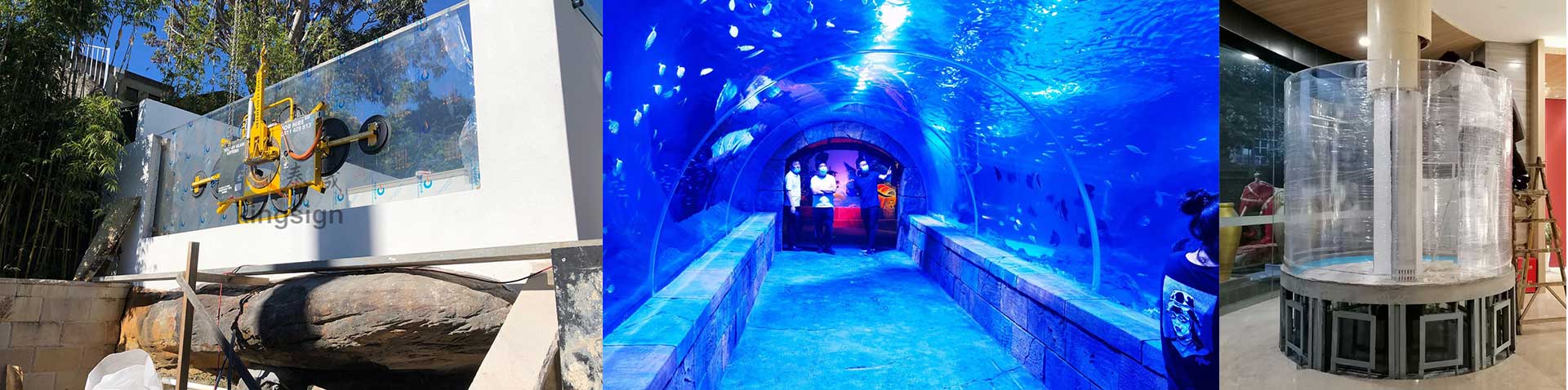

KINGSIGN® ACRYLIC is specialized in all kinds of Acrylic sheet, acrylic window, acrylic tunnel, acrylic marine hall, acrylic aquarium, acrylic swimming pool, acrylic fish tank, acrylic semi-finished processing parts, acrylic bonding acrylic glue, curved acrylic sheet, large-scale acrylic sheet installation service. for details, please consult: 0086 13370079013(Whatsapp/Wechat)