- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Can a pool window really stay crystal clear and safe for years?

2025-11-11

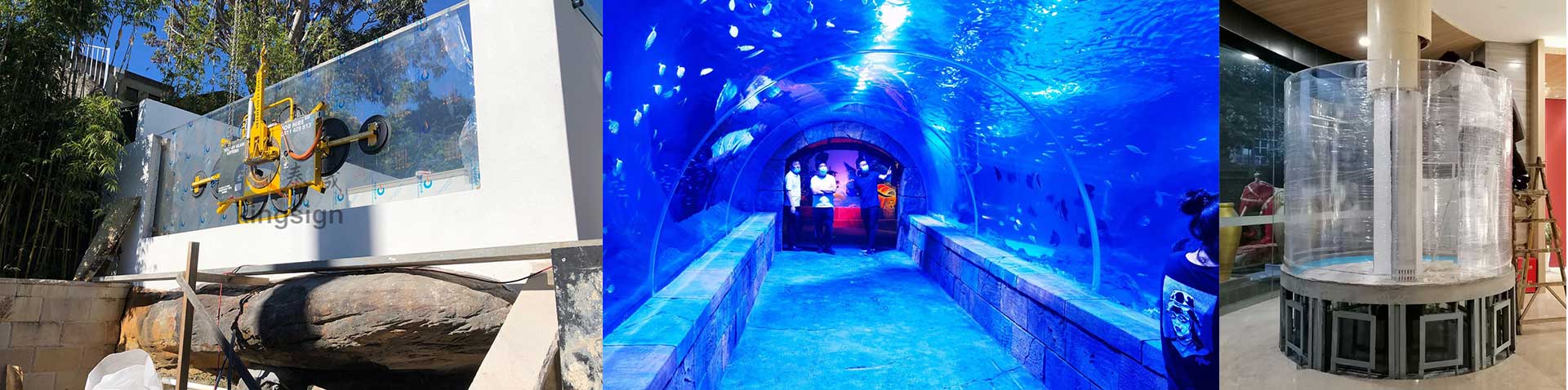

I didn’t fall for underwater views because of glossy renders; it happened on a humid site visit, watching kids press their palms to a clear wall while a swimmer slid past like a silhouette. That moment is why, whenever I design Pool windows, I obsess over long-term clarity, safe thickness and details crews can actually build. Materials decide most of it, and after enough projects I’ve learned that monolithic cast acrylic—often sourced from Kingsign for its big-block machining and stable optics—keeps the view calm and the maintenance predictable.

What shapes and sizes actually work without drama?

Acrylic gives me freedom that glass usually cannot. I have used side-wall viewing panels, corner wrap windows, floor portholes, even long ribbons that run the full length of a lap pool. Curves and L-shapes are realistic when the panel is machined from a single cast block instead of being laminated or glued in multiple pieces. Large ovens and five-axis CNC machining let me keep edges true and seams invisible.

- Monolithic cast blocks help avoid optical seams and delamination risk.

- Curved, angled, and tapered details are practical with precision machining.

- Floor windows and overflow edges need extra slip resistance and drainage planning.

Why do some panels yellow while others stay clear?

Discoloration usually traces back to resin purity and UV exposure. Cast acrylic with very low residual monomer content is more stable in sunlight. Kingsign’s curing process targets less than one percent residual monomer, which helps resist early yellowing under UV. The way a panel is heat-treated and stress-relieved also matters because internal stress can accelerate craze lines when the surface is cleaned or exposed to temperature swings.

- Low residual monomer supports long-term optical stability outdoors.

- UV stabilizers and proper annealing reduce crazing and micro-cracks.

- Avoid solvent cleaners; use pH-neutral agents and soft pads for routine care.

How do I choose acrylic thickness without guessing?

Water depth and free span set the starting point, then edge support and deflection limits refine the number. I run a finite element analysis to confirm safety factors and deflection under full load before I lock the thickness. The table below shows reference values I use in early conversations before engineering stamps the final design.

| Water depth | Free span | Typical acrylic thickness | Edge support condition | Notes |

|---|---|---|---|---|

| ~1.2 m | ~2.0 m | ≈ 60 mm | Four-sided rebate | Good for small residential windows |

| ~1.5 m | ~3.0 m | ≈ 75–100 mm | Three- or four-sided support | Common in boutique hotels and villas |

| ~2.0 m | ~4.0 m | ≈ 120–150 mm | Four-sided with structural frame | Deflection control becomes critical |

| ~3.0 m | ~5.0 m | ≈ 200 mm and up | Rebate plus compression gasket | Requires detailed engineering and bracing |

These ranges are for early budgeting and layout. I finalize thickness only after a project-specific FEA report shows stress and deflection within target limits.

What makes a monolithic panel different from laminated glass?

I lean toward cast acrylic when I need impact resistance, curved geometry or a virtually invisible edge. The comparison below mirrors what clients see in service.

| Aspect | Cast acrylic panel | Laminated glass |

|---|---|---|

| Impact behavior | Tough and ductile with high energy absorption | High stiffness but brittle failure mode |

| Weight per area | Lighter, easier craning and framing | Heavier, larger frames and foundations |

| Curves and shapes | Curves and complex edges are practical | Curves are limited and costly |

| Optical seams | Monolithic option with no glue lines | Lamination lines may be visible |

| Maintenance | Scratch repair by polishing is possible | Scratches are harder to correct |

How large can a single panel be before logistics take over?

Oversized blocks exceeding eleven meters in length and roughly three meters in height are practical when the factory has the oven capacity and the road permits allow transport. I plan crate dimensions early and check crane pick points, access routes and turning radii on site. Large one-piece panels eliminate vertical glue seams and keep the view clean.

What does a clean installation look like from the inside?

- Cast a smooth, level rebate or pocket in concrete with a continuous waterstop.

- Apply compatible gaskets and neutral-cure sealants specified for acrylic.

- Set the panel with even bearing and shim to maintain expansion gaps.

- Torque compression bars gradually and in sequence to avoid point loads.

- Protect the face film until handover and fill the pool in stages while monitoring deflection.

How do I control condensation and keep the view clear in winter?

Warm, humid air meets a cool panel and fog appears along the top edge. I address this with discreet air wash details, dehumidification and thermal breaks in the frame. Balanced water chemistry also preserves clarity because scale and oils leave films that exaggerate fogging.

What certification or testing should I ask for before I sign?

- Independent material reports confirming cast acrylic grade and mechanical properties.

- Third-party hygiene and safety testing performed by accredited labs to US-recognized standards.

- Project-specific FEA showing stress, deflection and safety factors at the design water level.

- Factory acceptance inspection with optical checks under raking light.

When do I bring the manufacturer into the conversation?

Early coordination saves money and keeps the architecture clean. I loop in the factory while the pool shell is still being drawn, which lets me tune the rebate depth, the expansion gap, and the frame geometry. Kingsign’s large-format ovens and precision machining shorten custom lead times because complex shapes are cut from a single block instead of assembled from smaller pieces.

How do I keep the window looking new after handover?

- Use soft microfiber pads and pH-neutral cleaners and avoid ammonia and solvents.

- Keep calcium hardness, pH and sanitizer within target ranges to limit film build-up.

- Schedule an annual polish for high-traffic commercial sites and a light restorative polish every few years for private homes.

What should I do next if I want a calm, picture-frame view instead of guesswork?

If you would like preliminary sizing, a concept sketch and a fast FEA-based check of thickness and deflection for your site conditions, contact us and tell me your water depth, clear opening and support on each side. I will return a concise proposal with options on shape, edge details and delivery. If you are ready to move forward, please contact us today and leave an inquiry with your drawings and timeline. I am happy to help turn your idea into a clear, durable window that keeps its sparkle season after season.